Underbelt Metal Detection

The 6600 Metal Detector for installation on inclined conveyors provides a solution to many metal detection problems. The use of this metal detector prevents damage to machinery resulting in lower repair costs and downtime. There will be an increase in recycled product value and a quick pay-back on capital investment.

The main features are:

- Low cost

- Easy to install

- Small, lightweight control unit

- Directly attaches to lightweight conveyors

- Detects both ferrous and non-ferrous metals

- Plug in search coils

- Sensing height of detector covers whole belt width

- Complies with CE-EMC regulations

- Reduced susceptibility to electrical noise

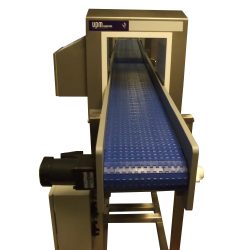

Tunnel Metal Detector

The tunnel range of metal detectors incorporate high sensitivity, balanced coil technology for detecting and removing ferrous, non-ferrous and stainless steel metal contaminants, ensuring product purity and machinery protection.

The main features are:

- Easy operation

- High sensitivity - balanced coil technology

- Single printed circuit board for ease of servicing

- Surface Mount Technology (SMT) for increased reliability

- Integral circuitry for remote operation and monitoring of reject devices

- Compliant with CE - EMC regulations

- Available in paint finish or stainless steel

- Push button selection of controls via on-board micro-controller

- Storage of up to 10 product settings

- Password protected

- 2 line LCD display of selected parameters

- Product compensation

Under Belt Cooling Fans

- Located beneath the 22% open link belt surface to blow ambient air onto product prior to discharge into storage container

- Quantity of fans depends on belt width and final product temperature required

- 175mm dia steel die cast aluminium frame with steel impeller

- Equipped with ball bearing and motor stall protection by temperature sensor with automatic reset

- 1ph 220v ac power supply

- Low noise 55 dBA

- Ambient airflow of 375 m3/h per fan

Air / Heat Exchanger Cooling

- Located above the belt surface to blow ambient or chilled air through the air / heat exchanger on to the product

- Quantity of fans depends on belt width and final product temperature required

- 175mm dia steel die cast aluminium frame with steel impeller

- Equipped with ball bearing and motor stall protection by temperature sensor with automatic reset

- 1ph 220v ac power supply

- Low noise 55 dBA

- Ambient airflow of 375 m3/h per fan