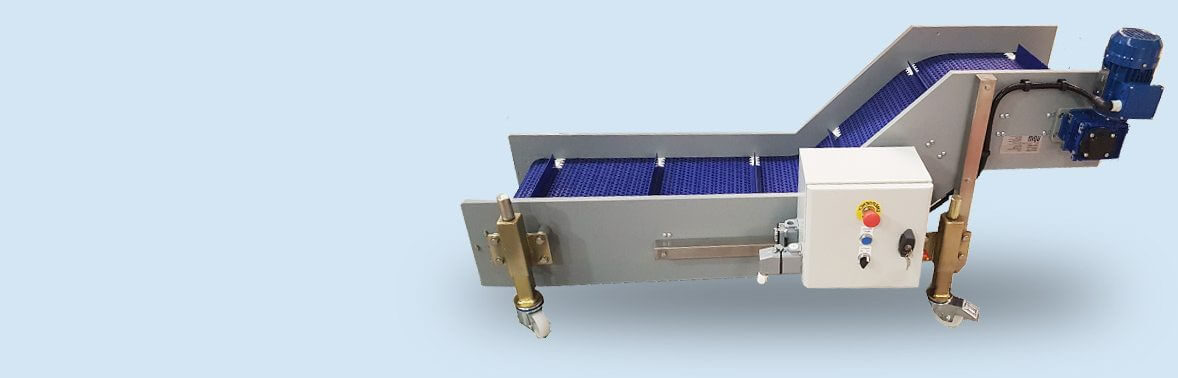

Conveyor Belts and Conveyor Systems

Conveyor systems for every industry

UPM Conveyors was founded in 1975 and specialises in providing conveying equipment for the world’s packaging industry. Since then, we have expanded extensively to include conveying food and hygiene-related products and still manufacture all of the conveyors at our UK factory in Langley, Berkshire.

We offer a diverse range of belt conveyors available in various sizes, designed for a wide range of uses, particularly in the construction industry for moving materials quickly and safely.

We have over 100 major installations worldwide and over 1,600 clients using our conveyor systems. We offer personal service to all of our customers and have a wide range of bespoke conveyors available for various industries, including packaging, food, hygiene products, and more.

UK Based Manufacturing Of Conveyors and Conveyor Systems

When working in the food or manufacturing industry, conveyor belts are a cornerstone of the process. At UPM, we offer a range of bespoke belt conveyor solutions, tailored to your exact requirements.

We have an in-depth knowledge of specification requirements for all types of industrial conveyor belts, from rollers to belts and more. We only use high-quality materials, and as a manufacturing company, we stay in total control during every stage of the process, so you can rest assured that your conveyor system will be provided exactly according to your needs. We handle everything in house, from initial design all the way to final installation.

Bespoke Conveyor Solutions

Industrial Conveyor Belt Solutions

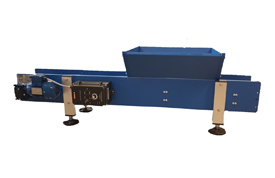

We offer a worldwide rapid service with tailored solutions. We are able to provide a range of tailored belt conveyors, from lazy Susans to counting and box filling conveyors. Our specialist team caters to a range of industries and has a number of different conveyor belts at hand for varying needs.

For any other conveyors that need to meet specific requirements, we can create versatile bespoke solutions using modern design and CAD systems. Our team of fully trained and equipped engineers also provides service support, so you never have to worry about maintenance issues.

All of our equipment is durable and high-quality, and has been manufactured and tested in accordance with the normative UK standards and conforms to all health and safety CE requirements.

High-Quality Conveyor Systems Built In The UK

Our high-quality conveyor units are suitable for industrial, warehouse, assembly, pharmaceutical, and food production applications. Our team of experts is on hand to answer any questions you may have about our conveyor systems, so please don't hesitate to contact us via phone or email.

Conveyor Case Studies

UPM – Another successful bespoke project with Lenham Storage

UPM Conveyors are proud to have been working with Lenham Storage for the second time on their new bespoke product handling system. About Lenham Storage Lenham Storage, based in Maidstone, Kent specialise in nationwide storage, FMCG storage and distribution. They serve manufacturers, importers and distributors and have recently had a multi-million pound investment in new […]